Project Details

BS Australia Pty Limited, a division of JBS, Brazil’s largest multinational in the food sector and the world’s largest meat company, sought to create an environmentally sound Hide Processing Facility. This facility would enable JBS to process hides in-house, allowing them to meet their increasing supplier demand while maintaining control over the environmental impact. Achieving this objective required a complete redesign of their entire process, ensuring the facility was both efficient and sustainable.

A key design consideration was the management of salt, specifically its use, storage, and recovery. Traditionally, the handling of salt in hide processing has had significant adverse environmental effects. JBS aimed to mitigate these impacts through innovative solutions integrated into the new facility.

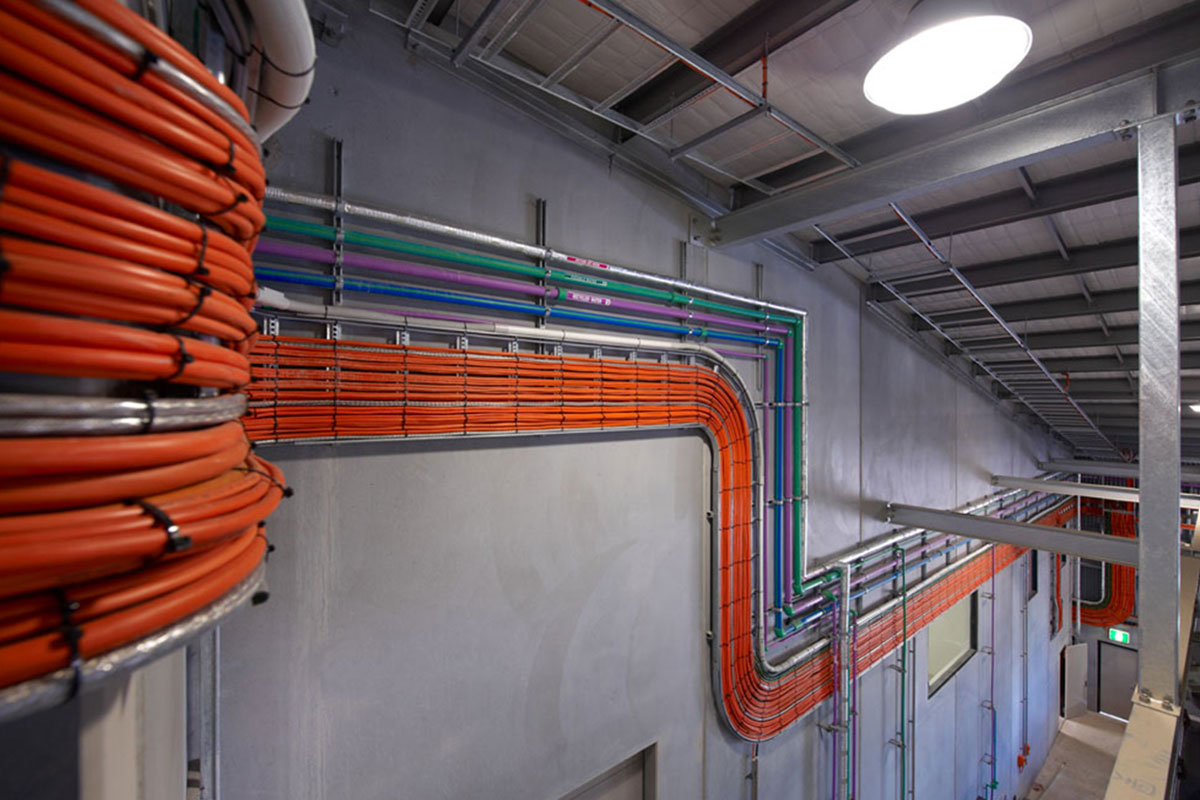

As a trusted electrical industrial contractor, CE Group was contracted to take on the critical task of designing and constructing the high-voltage (HV) and low-voltage (LV) switchgear and distribution systems. CE Group’s responsibilities also extended to motor control systems, complete with PLC and SCADA integration, which provided efficient automation and monitoring capabilities. In addition, CE Group handled the installation of general light and power systems, as well as the essential fire alarm systems.

Throughout the project, CE Group’s expertise ensured that all electrical components were designed and installed to the highest standards, meeting both environmental and operational goals. The comprehensive scope of works allowed JBS Australia to achieve its vision for a more sustainable, efficient hide processing facility. This project further solidified CE Group’s standing as a leading electrical industrial contractor, capable of delivering complex and environmentally conscious solutions in the food industry.